This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Is Spray Coating what you need?

Spraying a coil can achieve full coating when used on thin 3 rows or less coil construction and straight fins.

- Light weight

- Can be used on site

- Coil can be fully charged

- Speed of application

- High skill needed for good results

- Limited coil depth

- Over spray masking needed

- 50 % loss to atmosphere

Spray Coating Process

On arrival all units are thoroughly inspected...

before being disassembled for preparation.

They are then cleaned and dried...

before the Bronz-Glow coating can be applied.

The coating is then quality checked...

prior to re-assembly, a further inspection and preparation for

Do you have any questions?

Contact UsQuality Control and Order Progression

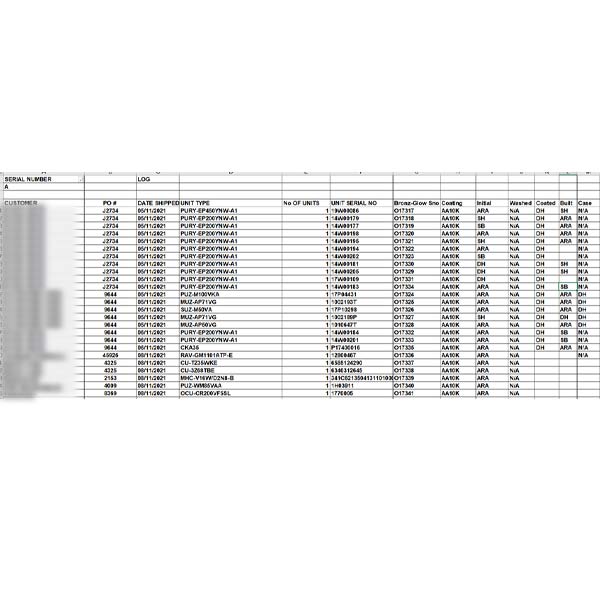

Each units Bar code is scanned on arrival and the procedure to be performed logged

If there is no bar code one is made to suit detailing the process to be performed

The bar code information is instantly uploaded to our unit log

This information is then transferred to our production tracking software

The unit details are instantly programmed into the WIP system and completion dates’ are complied

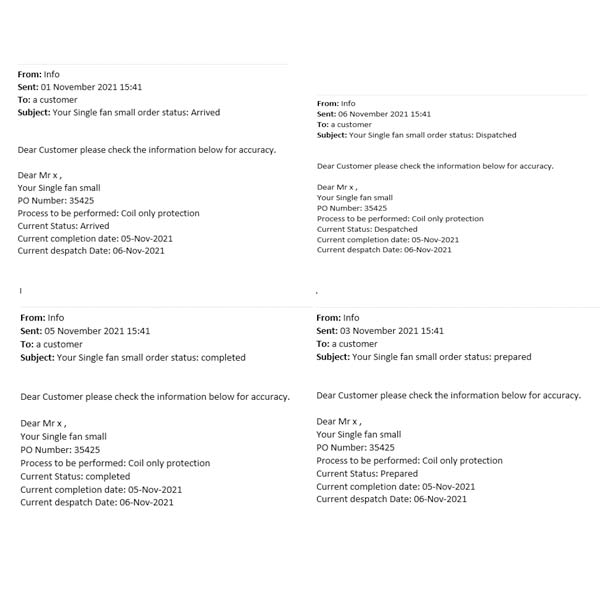

Automated E-mails’ are sent to the customer at each step to monitor progress

Do NOT be fooled!

Even with large fin spacing coverage is not guaranteed as can be seen, when a coil was sent to ourselves for re-coating after a poor spray attempt !!

It is not possible to cover 100% geometrically formed fins with spraying technique no matter how many rows.

With Immersion Coating, no matter how deep the coil you get total coverage

Do you need a more comprehensive coating method?

View Immersion CoatingIf you would like to know more about Spray Coating please call us on 01253 890666, email us at info@bronz-glow.co.uk