This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

This process is a step forward in coil protection and has been tested against alternative application technology and found to be > 95% of all surfaces coated in all cases.

The technology uses the surface tension of a liquid with a certain viscosity which will leave a train of coating to a very accurate depth, alter the viscosity alter the coating thickness. For example the viscosity of a fluid is a measure of its resistance to deformation at a given rate.

For liquids, it corresponds to the informal concept of “thickness”: for example, Honey has a higher viscosity than water. It is important to take into consideration the temperature and humidity, so coating thickness is less important in a coil with say 6 FPI but extremely important on a coil with 12 FPI. But in any application the thickness should not reduce the coil efficiency be more than 1%

Our cost always includes coil, base and return bends

Get in touchImmersion coating is the only way to guarantee full coverage.

Spray coating will not work on finely spaced fins or deep coils

Immersion coating works up to 20 rows deep and any fin geometry

Flow Coating

Water based Immersion Coating

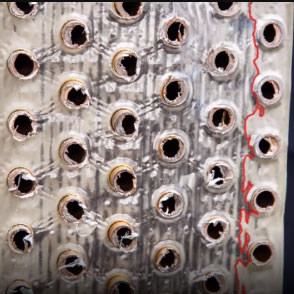

Some examples of how Spray Coating that hasn’t covered the coils as necessary

Before and after we fixed them

Corrective work needed at major retailed

Nice Unit

Shame about the coil

Nice unit

Shame about the coil

After we fixed it

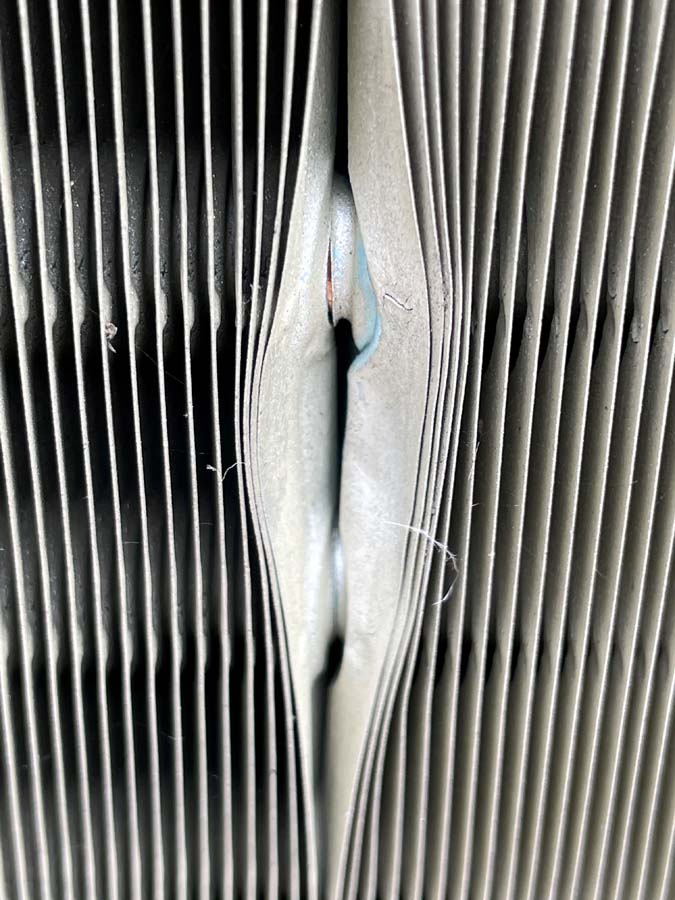

Deep Coil Showing poor penetration

Restrictions due to fin spacing and geometry cause pressure drop to occur and reduce or eliminate the ability to coat deep into a large coil this may also be a problem with smaller coils with a complex fin profile.

If you would like to know more about Spray Coating please call us on 01253 890666, email us at info@bronz-glow.co.uk